Material Testing Technology

© 2016-

Testing Machines

ASTM.G0065.10/ SAND WHEEL ABRASION TESTER

The Dry Sand/Rubber Wheel Abrasion Tester is used to test the abrasive resistance of solid materials to abrasive dry sand compositions. The Abrasion Tester can be used for specimens constructed from metals, minerals, polymers, composites, ceramics, abrasives, and/or thick coatings. A rectangular specimen is loaded against a rotating rubber wheel and the controlled grit size sand is deposited at a steady flow rate between them. The rubber coating on the wheel is 60 durometer Shore A hardness. The wheel rotates in the same direction as the sand flows. The mass of the test specimen is taken before and after completing the test. The resultant mass loss due to dry sand abrasion with a rubber wheel is the difference between the two figures. The mass loss must be converted to volume loss to rate and compare the test results between different material specimens. This Dry Sand/Rubber Wheel Abrasion Tester allows for variable test load and sand composition. Includes (1) Steel/Rubber wheel with 60 Durometer Shore A Scale hardness rubber, specimen holder and lever arm -

IMP.2011/ DROP WEIGHT IMPACTOR

Includes a 5.6 kg (12.35 lb) pound drop weight, impact tup with 0.625 inch diameter hardened hemispherical tip, twin guide rails that provide a minimum of 1000mm (36 inches ) of lift for the cross head weight. Supplied with fixtured specimen table, stop blocks, laser crosshead lift indicator, sturdy metal box frame construction, mechanical hoist lifting system, and latch mechanism.

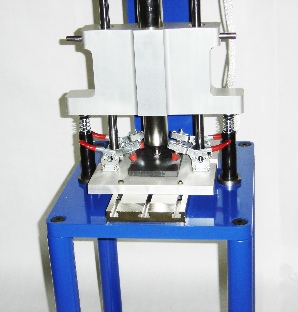

TORQUE TESTER

Movable Torque Drive Platform will be designed and fabricated to house the MTS (supplied) drive motor with gear reducer. The housing will be fabricated from solid metal and the reaction plate will be held in place with tie bars. The sides of the enclosure will be finished aluminum plates that are held in place with fasteners. Required indicator lights and controls with be recessed into one of the panels. The enclosure will be fitted with linear bearings that will ride on case hardened guide rails. The platform will house a six inch diameter motor. The torque drive platform will be free to move as needed for testing.

Torque Transmission System will attach directly the movable torque drive platform. The transmission bushing will permit near frictionless rotation movement of the drive shaft. The torque sensor, MTS(supplied), will be restricted from rotation movement by an “L” shaped aluminum bracket attached to the movable torque drive platform. The shaft will be supplied to the required end couplings for the torque sensor. The motor shaft will be adaptable to the 3 different rotary load cells.

Mechanical Interface for Customer Fasteners and Support Plate will be fabricated from quality steel with a protective black oxide oil finish. The fastener fixture will accept square fastener assemblies in the same fashion as existing equipment. The fixture will be supplied with a clamping bracket as on existing fixture. The fixture will be fastened to the support plate. The support plate will be supplied with through holes to fasten it to a table or bench (not supplied).