Material Testing Technology

Request Quote

© 2016- Material Testing Technology

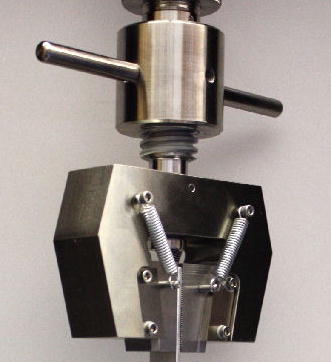

Titan Series Wedge Action Mechanical Grips

The manual wedge action grip is designed for easy specimen loading, alignment and positioning. After initial face to specimen contact, gripping force will increase as the testing load increases. This makes them particularly suitable for testing high strength materials, such as metals and composites, ensuring that specimen slippage is eliminated.

Principle of Operation

The wedge action principle of these grips allows them to be tightened onto a specimen without altering the vertical position of the faces in relation to the specimen. This is accomplished by a design, which moves the grip body to close the faces. This feature makes it possible to pre-select the exact point at which the specimen will be held with consistent gage length and no compressive force applied which may cause specimen buckling.

A strong clamping force can be applied to materials that are difficult to hold through a high mechanical advantage achieved by the tightening mechanism. The grip faces are spring loaded against a shoe which is in a fixed position in respect to the testing frame holding mechanism, only a light initial gripping force needs to be applied to the specimen. As the grip is tightened, it's frame is drawn up and the inclined sides push against the matching side of the faces which move laterally against the specimen. A shoe incorporated to the driving shaft prevents the faces from moving.

The open front design of the grip frames allows faces to be easily interchanged as well as easy specimen loading.

Because the faces are held in fixed position, there is no recoil, or loosening, when the specimen ruptures and if an extensometer is attached, it will remain in place.