Material Testing Technology

Request Quote

© 2016- Material Testing Technology

SCOPE: http://www.astm.org/Standards/B636.htm

ASTM B636 / B636M - 15

Standard Test Method for Measurement of Internal Stress of Plated Metallic Coatings with the Spiral Contractometer

1.1 This test method covers the use of the spiral contractometer for measuring the internal stress of metallic coatings as produced from plating solutions on a helical cathode. The test method can be used with electrolytic and autocatalytic deposits.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Extracted, with permission, from ASTM B636 Standard Test Method for Measurement of Internal Stress of Plated Metallic Coatings with the Spiral Contractometer, copyright ASTM International, 100 Barr Harbor Drive, West Conshohocken, PA 19482. A copy of the complet standard may be purchased from ASTM International, www.astm.org

Spare Parts:

Model No. EFTF.SM000.15 - Extra Helix for Gearless Spiral Contractometer Constructed of stainless steel and plastic.

Model No. EFTF.SM000.16 - Spare Parts Kit - (2) Set Screw 4-40, (2) Set Screw 6-32, (4) Set Screw 6-32 by 1/4”, (4) Set Screw 6-32 by 1/2”, (16) #6 Flat Washers, (2) #6 Hex Nuts, (4) Flat Washers, (8) Pan Head 6-32 by 1/2”, (8) Pan Head 8-32, (4) Pan Head 4-40, (8) Pan Head by 1/4”, (1) Hex Ball Driver 1/16”, (1) Hex Ball Driver 0.05”, (1) Screwdriver #1 Tip, (1) 6” Long Scale, (1) 7/64” Drill Bit, (1) 13/64 Drill Bit, (2) Calibration Weights

Accessories:

Model No. EFTF.SM000.11 - 4,000 ml Pyrex Beaker

Model No. EFTF.SM000.12 - Titanium Anode Basket

Model No. EFTF.SM000.13 - Stirring Hot Plate, 115 Volt

Model No. EFTF.SM000.14 - Precision 10A Power Supply with Timer, 115 Volt

Model No. EFTF.SM000.17 - Tank Mounting Bracket for Contractometer

Model No. EFTF.SM000.20 - Complete Benchtop Gearless Spiral Contractometer System - System includes gearless spiral contractometer, 4,000 ml Pyrex beaker, titanium anode basket, and precision 10A plating power supply. 115 Volt

Model No. EFTF.SM000.21 - 1-20V Output, 0-10A Output Current Rectifier

Quote: Model No. EFTF.SM000.10

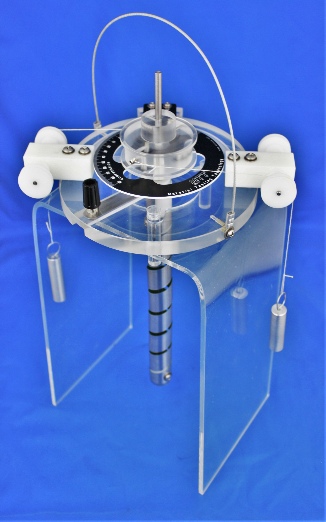

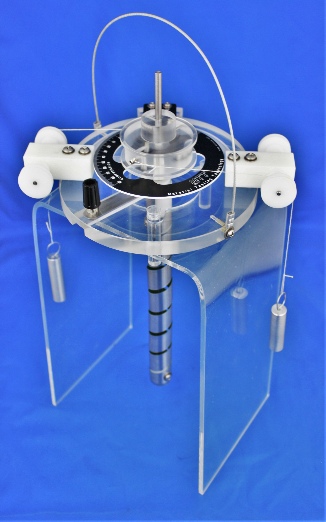

Gearless Spiral Contractometer

The Contractometer is used for measuring stress in plating tanks. By submerging the helical sensor portion of the Contractometer in the plating bath solution, and allowing approximately 0.0005” of metal to be deposited on the outside of the helix, the stress can be determined. The helix will contract or expand depending on the stress involved. The Contractometer includes the handle, body, weight system with (2) weights, circular scale, and the helix. Constructed of plastic, acrylic and stainless steel.

|

Fixture:

|

Construction

|

Acrylic, plastic, and stainless steel

|

|

|

Temperature

|

Ambient

|

|

|

Mounting

|

Titanium anode basket

|

|

|

Weight

|

11 lbs approximately

|

|

|

Dimensions

|

8” x 6” x 12”

|

|

|

Standard

|

Manufactured in accordance with ASTM B636

|

GEARLESS SPIRAL CONTRACTOMETER